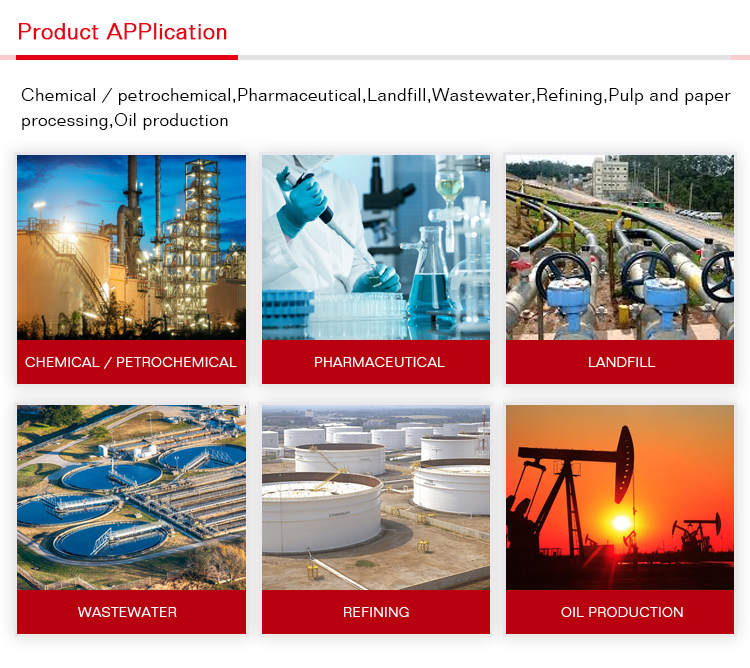

Producdt Description

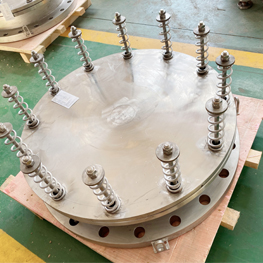

In Line Flame Arrester is mainly composed of shell and fire element. There are two kinds of commonly used metal mesh filter element and corrugated filter element. The metal mesh filter element is composed of stainless steel or copper mesh with a diameter of 0.23-0.315 mm and overlapping layers. In Line Flame Arrester in China usually use 16-22 mesh metal mesh with 4-12 layers.

The corrugated filter element is supported by stainless steel, copper-nickel alloy, aluminium or aluminium alloy. Corrugated flame retardant can prevent the fierce flame of deflagration, and can withstand the corresponding mechanical and thermal effects, flow resistance is small, easy to clean and replace.

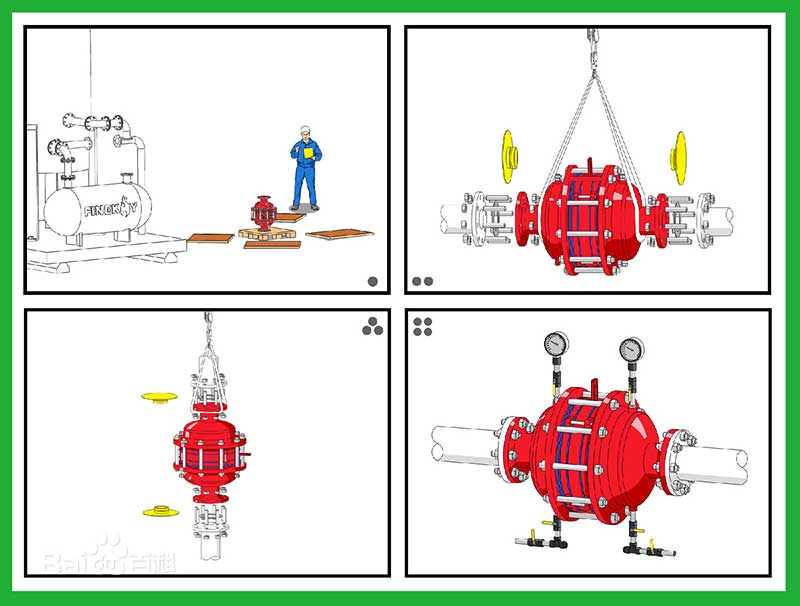

Installation:

- Remove all flange cover and discard all packaging materials.

- Check the seat, the matching flange gasket on the seat surface. It must be clean, flat, scratch-free, corrosion-resistant, tool traces.

- Check the gasket to ensure that the material is suitable forapplication.

- Lubricate all studs and nuts with proper thread lubricant. If the fastener is a high temperature stainless steel material, a back-grabbing compound, such as molybdenum disulfide, is used.

- Inside gasket of bolt ring.

- Installing flange of Inline flame arrester shell to butt with flange of pipeline, attention should be paid to the position of lifting handle and top nut of In line flame arrester element to facilitate the removal of In line flame arrester elements in the future.

Note:

Under normal circumstances, (fire) breathing valve operating pressure to B shall prevail;

Applicable materials: gasoline, kerosene, diesel, aromatics, sulfur, air and other petrochemical materials;

Environment temperature: -40 °C -+60 °C;

Shell material: HT, AL, A3, 18-8, 304, 304L, 316, 316L.

Flange standards: HG20592-97 PN1.0 (also can be produced according to user specified criteria)