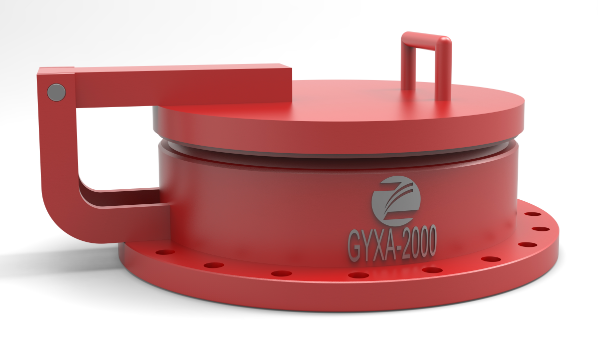

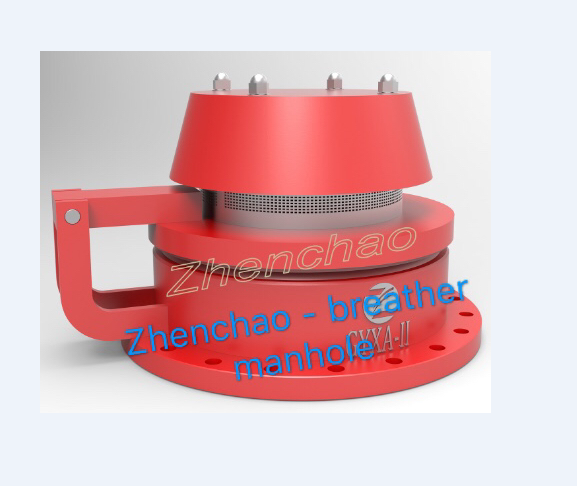

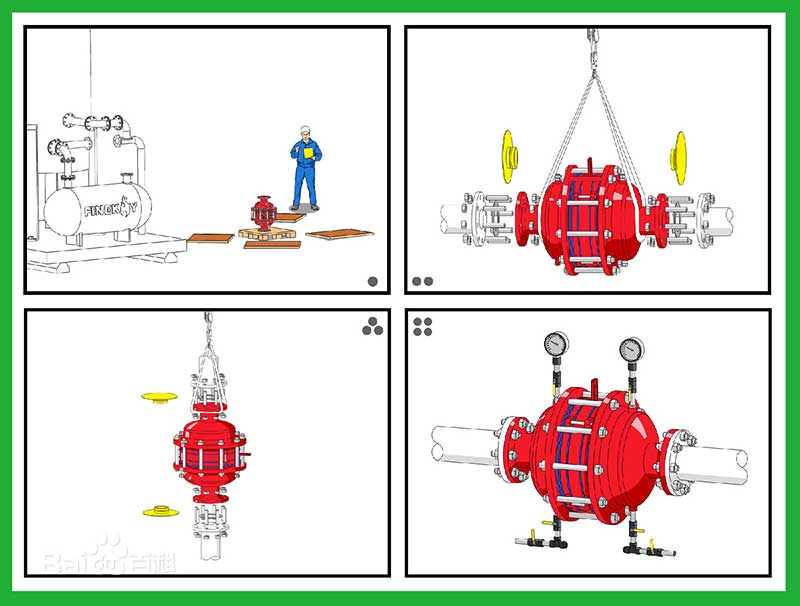

Producdt Description

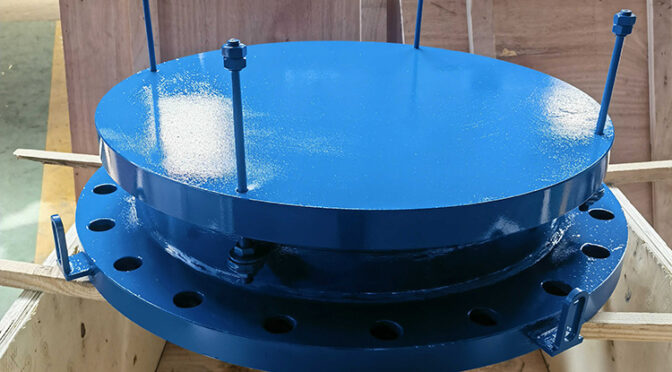

Operating pressure:

Note:

Under normal circumstances, (fire) breathing valve operating pressure to B shall prevail;

Applicable materials: gasoline, kerosene, diesel, aromatics, sulfur, air and other petrochemical materials;

Environment temperature: -40 °C -+60 °C;

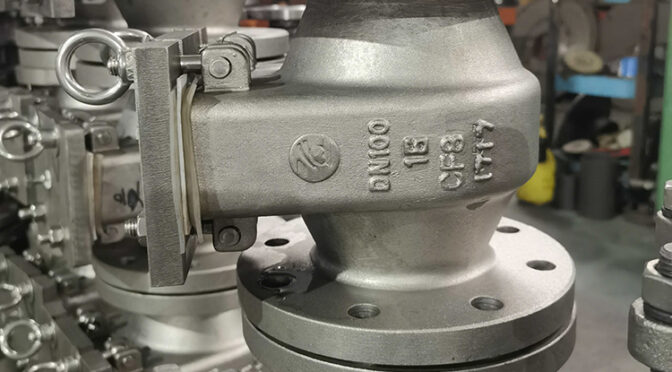

Shell material: HT, AL, A3, 18-8, 304, 304L, 316, 316L.

Flange standards: HG20592-97 PN1.0 (also can be produced according to user specified criteria)