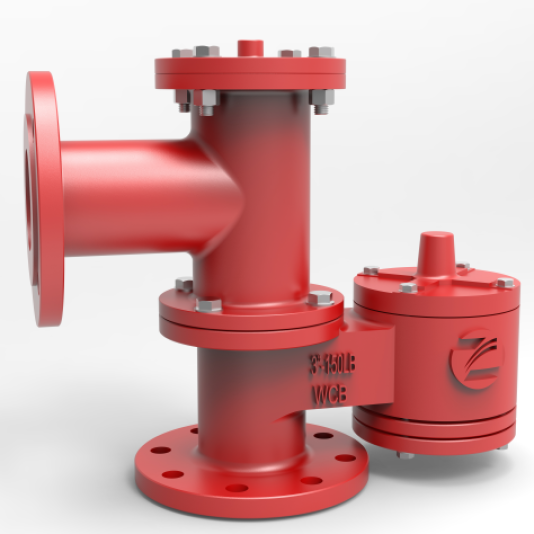

Producdt Description

ZCPE-pilot operated breather valve with flame arrester is a bit different with breather valve ,first let the seat leakage closer to set point ,second full flow without overpresure ,to maintain the tank pressure balance, reduce safety energy-saving products medium volatile, but also the use of principles of vapor heat transfer, protect the respiratory valve parts is not easy to freeze, the breathing valve to ensure the normal work, equipped with fire retardant explosion-proof function.

Fire breathing valve produced by our company has simplified structure, ventilation volume, less leakage, corrosion resistance, insulationetc.. The valve adopts polytetrafluoroethylene material, has the advantages of low temperature resistant, anti frost. The electrostaticprotection device is provided with a respiratory valve, the valve and the tank to keep the same potential moment.